2025.06.13

2025.06.13

News

News

The primary function of a plastic precision mold is to create components with consistent and exact measurements. In industries where precision is paramount, such as the automotive, electronics, and medical sectors, the need for molds that can produce parts to tight tolerances is critical. A slight deviation in measurements can bring about defective products, resulting in costly rework, wasted materials, and a loss of consumer trust.

Plastic precision molds are engineered with high levels of accuracy, ensuring that the end product meets the required specifications. With advancements in computer-aided design (CAD) and computer-aided manufacturing (CAM), molds can now be designed and produced with microscopic levels of precision. This capability enables manufacturers to create intricate components with complex geometries, which would be difficult or impossible to achieve using traditional manufacturing methods. For instance, parts like circuit boards for electronics, medical implants, or engine components for vehicles require the precision to function as intended.

Another vital advantage of plastic precision molds is their ability to streamline production processes, thereby enhancing manufacturing efficiency. In mass production, time is of the essence, and having a mold that can produce thousands or even millions of identical components quickly is a game-changer. Plastic molding allows for high-volume manufacturing with minimal intervention, reducing labor costs and human error. Once a mold is designed and produced, it can be used repeatedly to produce identical parts without the need for retooling or adjustments.

The automation of the molding process further improves efficiency. Machines can operate around the clock, reducing production downtime and ensuring a constant supply of products. This is especially beneficial in industries like consumer goods, where fast turnaround times are essential to meet market demands. The ability to produce large quantities of high-quality parts in a relatively short amount of time makes plastic precision molds an indispensable tool for modern manufacturing.

Moreover, the use of precision molds minimizes material waste. In traditional manufacturing methods, excess material is often discarded, bring about inefficiency and increased costs. With plastic precision molds, the amount of material used is carefully controlled, reducing waste and improving the overall cost-effectiveness of the production process. This not only benefits manufacturers but also aligns with sustainability efforts by environmental impact.

Plastic precision molds are incredibly versatile, enabling the production of a wide range of products across various industries. The molds can be designed to accommodate different types of plastics, including thermoplastics, thermosets, and elastomers, each of which has unique properties suited to different applications. Whether the requirement is for a rigid automotive part, a flexible medical device, or a lightweight consumer good, precision molds can be adapted to meet the specific needs of the product.

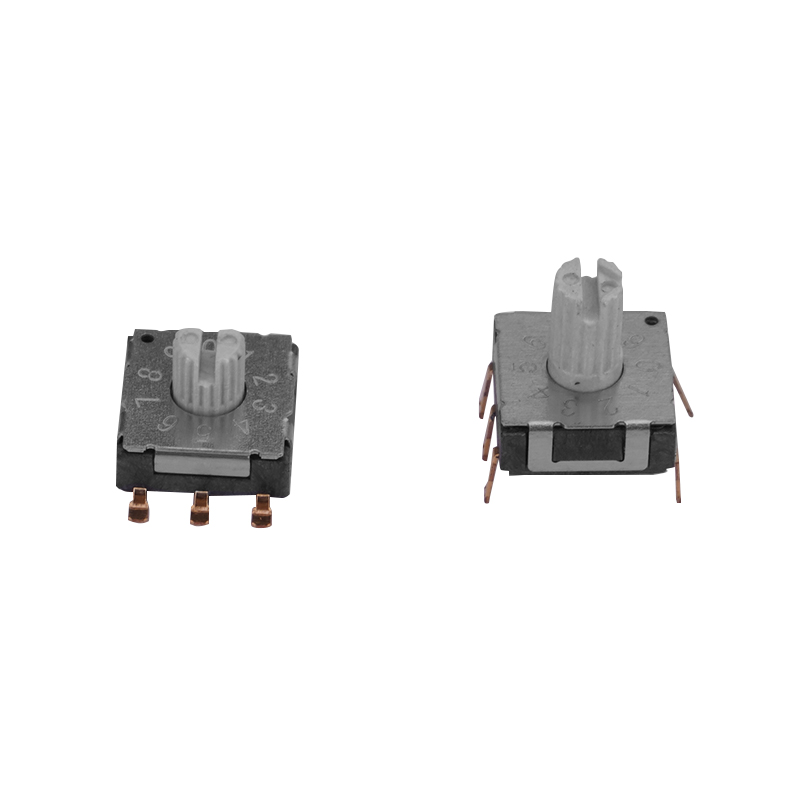

In addition to material versatility, molds can be designed to produce components with complex shapes, including intricate details like undercuts, textures, and thin walls. This flexibility in design is particularly important in industries like electronics, where components often have to fit into compact spaces and accommodate a variety of functionalities. For example, plastic precision molds are used to create components such as connectors, casings, and housings for smartphones, laptops, and other electronic devices, all of which require precise dimensions and smooth finishes.

The versatility of plastic precision molds also extends to customization. Manufacturers can easily alter existing molds to produce different versions of a product, making it possible to introduce design variations without the need for entirely new molds. This adaptability is crucial in industries like fashion and consumer goods, where design trends change rapidly, and quick turnaround times are essential to staying competitive in the market.