2026.02.20

2026.02.20

News

News

The ubiquitous plastic cable tie, a staple of organization in industries from electronics to agriculture, begins its life not as a strip of nylon but as a precisely engineered steel cavity. The Polypropylene (PP) Seal Cable Tie Mold is a sophisticated injection mold dedicated to mass-producing these consistent, reliable fasteners. Its design is a masterclass in balancing high-volume output with the intricate requirements of a functional, one-piece living hinge design. This article will examine this essential tool from four key aspects: its core function and components, the critical design of its forming surfaces, the complex systems that enable its operation, and the material and manufacturing considerations that define its use.

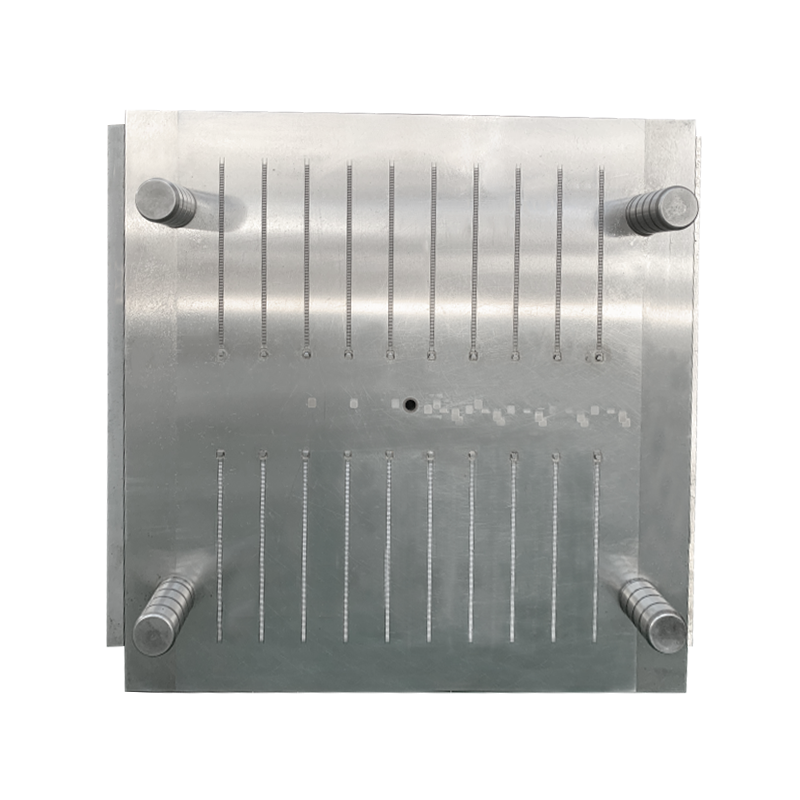

The primary function of the PP seal cable tie mold is to form molten polypropylene into a specific, net-shaped part within a fraction of a second. This occurs inside the high-pressure environment of an injection molding machine. The mold itself is not a single unit but a system of integrated components. Fundamentally, it consists of two halves: the stationary "A" plate, which is fixed to the injection molding machine and interfaces with the plastic injection nozzle, and the moving "B" plate, which opens and closes the mold cycle. Within these plates are the core and cavity inserts—the hardened steel blocks machined with the inverse geometry of the cable tie. The mold also incorporates an ejection system, typically consisting of pins or blades, which pushes the solidified tie out of the cavity once it is cooled and the mold opens. The precision with which these components are aligned and manufactured directly dictates the quality and consistency of every tie produced.

The most critical aspect of the mold is the design etched into the steel of the core and cavity. This design must accurately replicate every functional feature of the finished cable tie. These features include the precise length, width, and thickness of the strap; the fine, angled teeth of the locking mechanism; and the delicate living hinge that connects the strap to the locking head. The mold surfaces must have an exceptionally fine finish to allow the part to eject cleanly without sticking, and to ensure the strap has a smooth surface to prevent snagging. Furthermore, the cavity is often designed as a "family mold," meaning it contains multiple identical cavities—sometimes 16, 32, or more—arrayed around a central feeding system to maximize output per machine cycle. The layout and machining of these multiple cavities require extreme precision to ensure every tie produced in a single shot has identical properties.

A high-volume production mold is more than just a shaped block of steel; it is a thermal management system. The rapid cycling of an injection mold, often in intervals of 10-20 seconds, is impossible without efficient cooling. A network of internal channels is drilled through the mold plates, through which temperature-controlled water is constantly circulated. This system extracts heat from the molten plastic, solidifying it quickly and uniformly to prevent warpage and ensure dimensional stability. Equally important is the ejection system. Given the cable tie's slender form and undercut teeth, ejection must be carefully engineered. Ejector pins are positioned strategically to apply even force without damaging the part. The timing and stroke of this system are synchronized perfectly with the mold opening sequence to ensure parts are cleanly and reliably deposited for collection or automated packaging.

The choice of mold steel and the protocols for its upkeep are decisive factors in the mold's economic lifespan and part quality. The demands of high-volume production, abrasive filler materials sometimes present in PP, and constant clamping pressure necessitate a durable material. A common choice is pre-hardened steels like P20 or harder, corrosion-resistant options like H13 stainless steel, often with specialized coatings like chromium or nickel for enhanced release and wear resistance. The maintenance requirements are systematic and critical. The following table outlines the key considerations:

|

Aspect |

Typical Specification |

Purpose & Rationale |

|

Mold Steel |

P20, H13, S136 |

Provides necessary hardness, polishability, and resistance to wear and corrosion. |

|

Surface Finish |

High polish (e.g., SPI A1) on cavity surfaces |

Ensures easy part ejection and a smooth finish on the cable tie strap. |

|

Regular Maintenance |

Cleaning, lubrication of guide pins, inspection for wear |

Prevents downtime, maintains part quality, and extends mold service life. |

|

Common Wear Points |

Locking tooth details, gate areas, ejector pins |

These high-stress areas require periodic inspection and potential refurbishment. |