2025.09.26

2025.09.26

News

News

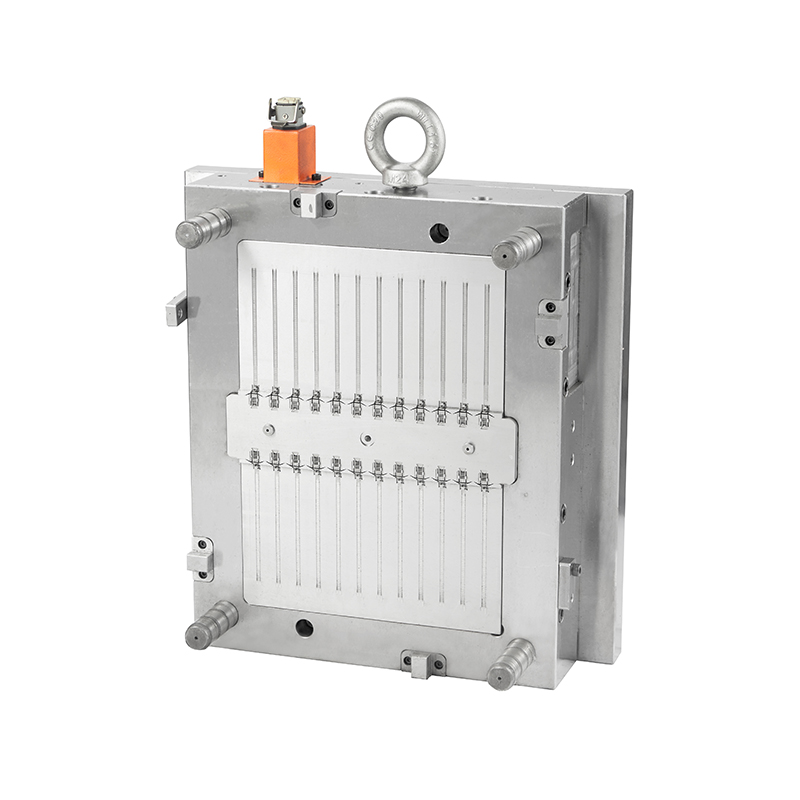

Threaded head cable tie molds are essential tools in the production of cable ties used in various industries. These molds are specifically designed to create the threaded head of cable ties, which allows for secure fastening and easy adjustments. With their robust design and ability to produce precise and reliable cable ties, threaded head cable tie molds play a key role in the manufacturing process.

Key Features of Threaded Head Cable Tie Molds

1. Precise and Consistent Production

One of the primary features of threaded head cable tie molds is their ability to produce highly accurate and consistent cable ties. The threaded head design is crucial for ensuring that the cable tie can be tightened securely and adjusted easily. These molds are crafted to exacting specifications, allowing for the creation of cable ties with uniform thread profiles. This consistency in the molding process ensures that each cable tie performs reliably in applications requiring secure bundling or fastening.

The precision of the mold allows for a high degree of repeatability, making it possible to produce large quantities of cable ties that meet strict quality control standards. This feature is especially important in industries like electronics, automotive, and telecommunications, where consistent performance is critical.

2. Durability and High Performance

Threaded head cable tie molds are designed to be durable and withstand the wear and tear of continuous production runs. Made from high-quality steel or alloy materials, these molds are built to endure the pressure, heat, and stress associated with the injection molding process. The durability of these molds ensures that they can produce thousands, or even millions, of cable ties without significant wear or degradation in quality.

The high-performance design of the mold allows it to produce cable ties that are strong, resilient, and capable of holding up under various environmental conditions. These ties are often exposed to harsh conditions, such as high temperatures, moisture, or chemicals, and the molds help ensure that the finished product is up to the task.

3. Customization for Different Cable Tie Sizes

Threaded head cable tie molds can be customized to produce a variety of tie sizes and shapes. This flexibility is important in applications that require different cable tie lengths, widths, and thread types. The ability to customize the mold to suit specific needs means that manufacturers can produce cable ties for a wide range of uses, from small-scale electronics to large industrial applications.

Custom molds allow for adjustments in the size of the threaded head, ensuring that the cable tie fits a variety of cable diameters and offers an appropriate level of clamping force. The design of the mold can also accommodate different materials, such as nylon, polypropylene, or other plastics, depending on the application’s requirements.

4. Efficient Manufacturing Process

Threaded head cable tie molds are integral to an efficient manufacturing process. The use of high-quality injection molding techniques ensures that cable ties are produced quickly and with minimal material waste. The injection molding process allows for the creation of cable ties at a rapid pace, with each mold cycle lasting only a few seconds. This efficiency is crucial for mass production, where downtime and throughput are key to reducing manufacturing costs.

In addition to speed, the molding process also contributes to the overall strength and consistency of the finished product. Since the material is injected under pressure, it fills the mold uniformly, ensuring that the final cable tie is solid and free from defects such as air pockets or weak spots.

5. Ease of Maintenance

Threaded head cable tie molds are designed to be easy to maintain, which helps ensure their longevity and consistent performance. Regular maintenance, such as cleaning the mold cavity and lubricating moving parts, can prevent material buildup and ensure that the mold continues to operate at peak efficiency. Many molds also feature modular components that can be replaced individually, which helps minimize repair time and costs.

In addition, some molds are designed with self-cleaning features or have removable parts that allow for easy access to the interior of the mold, making routine maintenance more straightforward. Proper maintenance not only helps extend the lifespan of the mold but also ensures that the cable ties produced meet the required quality standards.

Precautions When Using Threaded Head Cable Tie Molds

1. Proper Mold Storage

Molds should be stored properly to prevent damage and ensure their longevity. Threaded head cable tie molds are precision tools that can be sensitive to environmental conditions. They should be stored in a dry, cool, and dust-free environment to avoid rust, corrosion, or the buildup of debris that could affect the quality of the cable ties produced. If molds are not in use for an extended period, it’s advisable to clean and coat them with a protective layer to prevent oxidation.

2. Regular Cleaning and Inspection

Routine cleaning and inspection of the mold are essential for maintaining its functionality and preventing defects in the molded cable ties. Residual plastic, dirt, or other contaminants can accumulate within the mold cavity over time, affecting the molding process and the quality of the final product. Regular cleaning ensures that these residues are removed and that the mold cavity remains smooth and free from obstructions.

In addition to cleaning, it’s important to inspect the mold for signs of wear or damage. Common issues such as cracks, dents, or misalignments can impact the precision of the molded cable ties and production delays or defective products. Any issues should be addressed promptly to avoid costly repairs or replacements.